Profile production equipment

Product

Contact

- No.188, Zhenbei Road, Leyu Town, Zhangjiagang, Jiangsu, China.

- +86-0512-58609008

- +86-0512-58669008

- sales@cxsljx.com

产品介绍

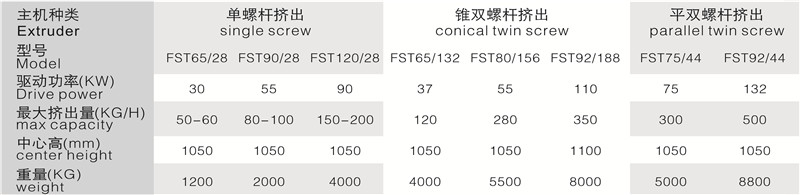

PE/PP/PVC Wood-Plastic Extrusion Production Line

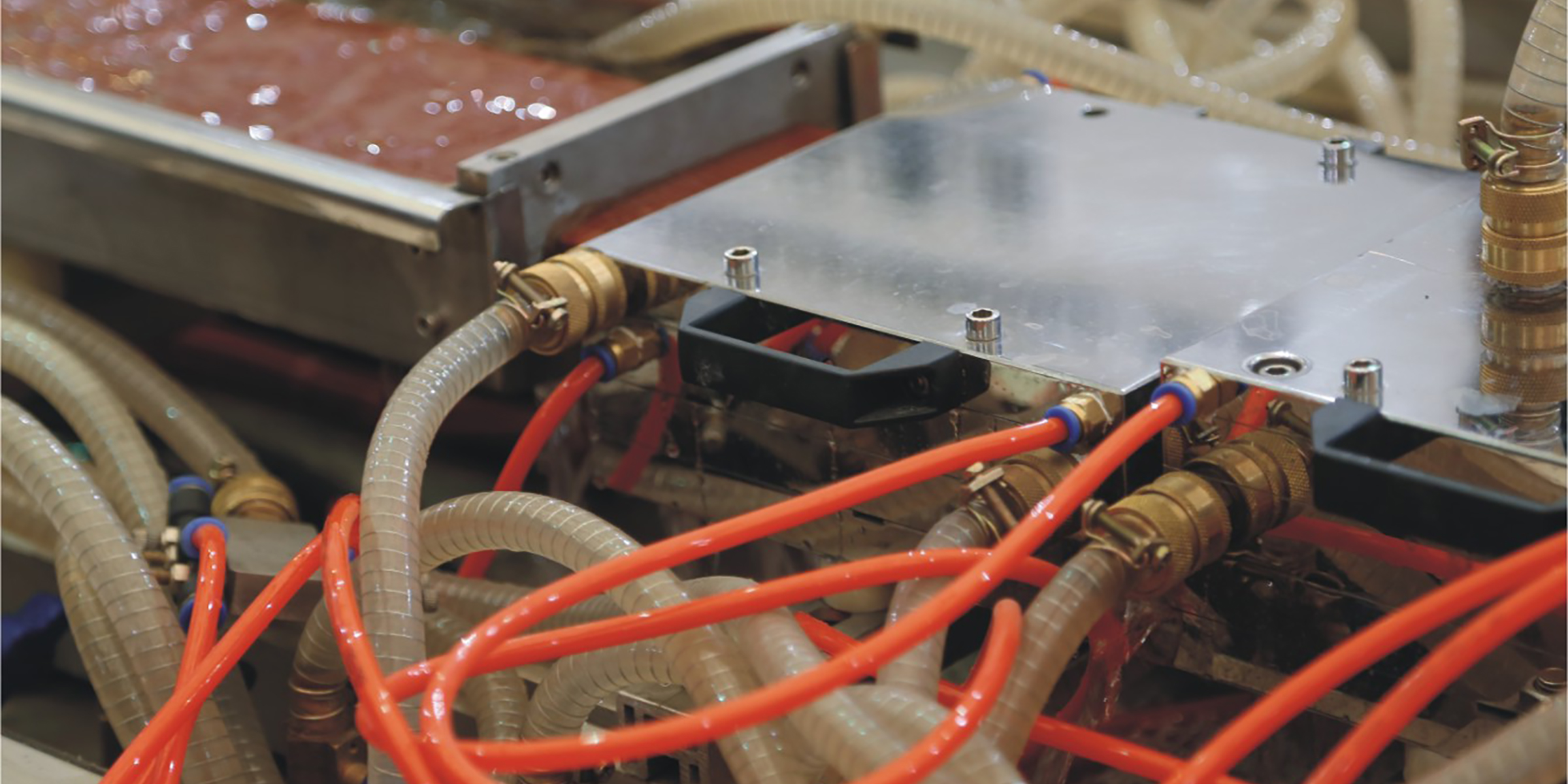

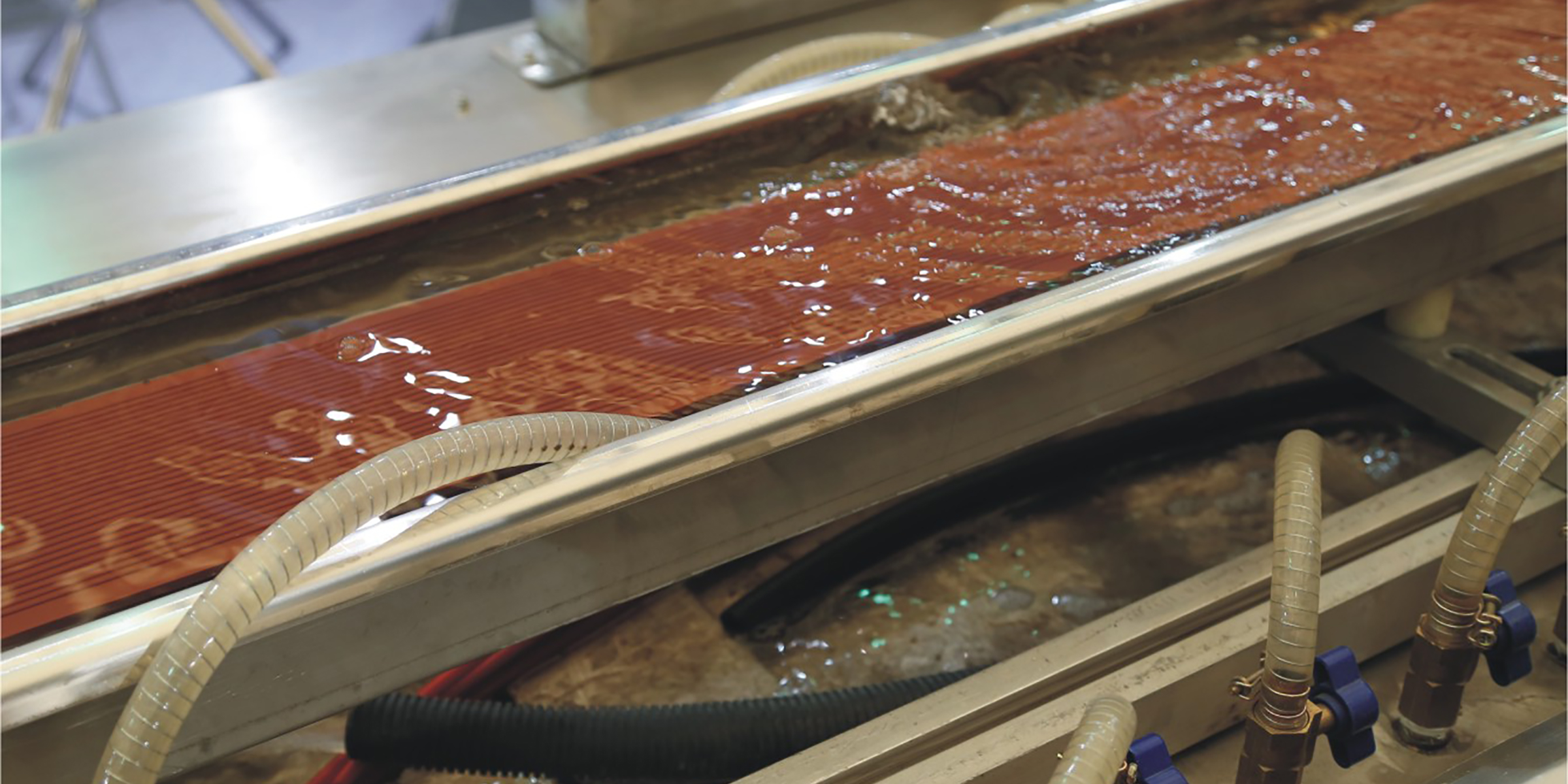

Wood-plastic extrusion production line uses specially designed screw barrel, die and extruder processing technology to produce wood-plastic products. The company's product series, wood-plastic one-step thick plate equipment, wood-plastic one-step profiles equipment, wood-plastic one-step decoration equipment, wood-molding granular equipment, a variety of wood-plastic molds.

The extruder can be directly extruded by two-stage mixing in a single machine or by two-step extrusion after granulation, which saves power and space. It has the characteristics of high output, stable extrusion pressure, and the preheating feeder is placed on the top of the main machine. The residual moisture in most wood flour is extracted first, so that the main feeding section is more substantial and the plasticizing mixing effect is good. The optimized screw design makes the shearing small and the wood fibre difficult to cut, and makes the material stay in the machine even. The screw barrel is treated with bimetal, which is wear-resistant and corrosion-resistant, and its service life is greatly prolonged.

The production line produces PE, PP or PVC wood-plastic profile products, mainly used for pallets, packing boards, floors, outdoor decorative materials, etc., with a wide range of uses. Wood flour and vegetable fiber are added in high quantity (up to 50-75%). The equipment has strong adaptability, and can process PP, PE, PVC, ABS, PS and so on at the same time.

在线询价:

如果你有任何问题,反馈或意见,请填写下面的表格,我们会尽快回复你。